Tesla’s Optimus Robot Updates: From Factory Prototype to Workforce Reality

Published on: 2025-10-26 • Category: Robotics • By Timeless Quantity

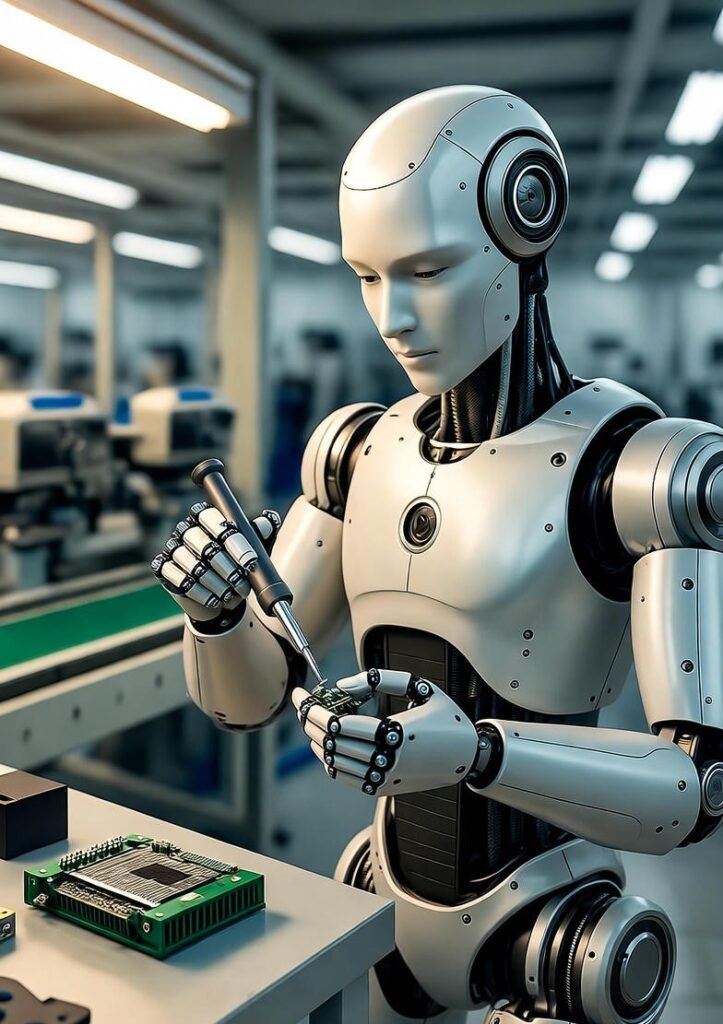

Key Takeaway: Tesla’s humanoid robot, Optimus, has achieved new levels of dexterity and perception that could soon allow autonomous operation in Tesla factories. With incremental AI upgrades, improved hand articulation, and spatial awareness, the robot now performs object sorting, packaging, and basic assembly — moving closer to functional deployment on the production floor.

From Concept to Factory Prototype

When Elon Musk first introduced Optimus in 2021, the vision was grand but the prototype rudimentary. Four years later, the 2025 version reflects a disciplined evolution — from stage demo to functional factory unit. The robot now performs pick-and-place tasks, organizes parts trays, and navigates industrial environments without remote operators. Tesla engineers describe Optimus not as a novelty, but as a practical extension of the company’s core competency: vertical AI integration across hardware and software.

The significance lies in Tesla’s data advantage. The company’s self-driving stack, honed across billions of real-world miles, forms the foundation for Optimus’s vision, planning, and reinforcement learning systems. The same neural networks that teach cars to drive are now teaching robots to work.

Dexterity and Perception Upgrades

Early Optimus iterations struggled with basic manipulation — slow, jerky motions and poor object generalization. The 2025 model, however, features individually actuated fingers, real-time tactile sensing, and multimodal perception combining vision, touch, and proprioception. This allows the robot to handle delicate objects, operate tools, and adjust its grip dynamically based on material resistance.

- AI-Driven Motor Control: Reinforcement learning enables continuous refinement of micro-movements.

- Spatial Awareness: Depth mapping and environmental reconstruction help Optimus avoid collisions in cluttered spaces.

- Task Adaptability: The robot can generalize from demonstrations to new but similar assembly tasks without explicit programming.

These capabilities echo the human learning curve — iterative, data-driven, and context-sensitive — marking a key step toward reliable human-robot collaboration.

AI Autonomy: Beyond Pre-Programmed Motion

Optimus’s new autonomy layer leverages Tesla’s in-house AI compute clusters, using the same Dojo supercomputer that trains self-driving models. Each robot records and uploads sensor data from task repetitions, enabling collective learning across the fleet. In practice, that means one robot mastering a task can propagate that skill to every other Optimus via parameter updates.

This distributed training system is the foundation of Tesla’s “Software 2.0” philosophy: a loop where physical experience feeds digital intelligence. The result is a learning infrastructure that scales robot capabilities much like over-the-air updates scale vehicle performance.

Practical Applications in Tesla Factories

According to Tesla engineers, the first production use cases will appear in gigafactories — environments with repetitive, structured tasks and controlled safety conditions. Optimus units are expected to:

- Assist human workers with parts handling and inventory logistics.

- Perform subassembly tasks like cable routing or component inspection.

- Operate side-by-side with humans under safety protocols using force sensors and vision fencing.

- Reduce downtime by autonomously identifying missing parts or rebalancing workflows.

Each successful deployment feeds data back into training pipelines, refining perception and control across all robots.

The Economics of Humanoid Labor

The pitch for Optimus extends beyond Tesla’s own factories. Musk has stated that humanoid robots could eventually become a multi-trillion-dollar market — “bigger than cars.” The logic is straightforward: a robot that can handle physical labor in human spaces could transform manufacturing, logistics, and even domestic work.

Early deployments will focus on cost reduction, not replacement. A robot that works 24/7 without fatigue could offset labor shortages and stabilize throughput, but only if unit costs and reliability converge. Tesla’s vertical integration — from actuators to chips to AI stack — is its edge in driving down bill of materials and training costs simultaneously.

The Global Race Toward Humanoid Robotics

Tesla is not alone. Companies like Figure, Agility Robotics, Apptronik, and Boston Dynamics are racing toward general-purpose robots. Figure’s partnership with BMW and Agility’s integration pilots with Amazon signal accelerating commercialization. Tesla’s differentiator remains its data and deployment scale — no competitor matches the quantity of synchronized hardware operating under unified training pipelines.

As humanoids become practical, expect differentiation to pivot toward software sophistication — natural-language tasking, error recovery, and collaborative safety. Tesla’s experience with real-world autonomy gives it a formidable advantage in all three domains.

What Comes Next for Optimus

The roadmap ahead likely includes:

- Full-shift endurance testing across multiple gigafactories.

- Vision-language interface enabling workers to command robots via natural speech.

- Enhanced locomotion — faster walking speeds and obstacle recovery.

- Public demonstrations of complex cooperative tasks to validate safety for broader industrial adoption.

Each iteration inches closer to the long-term vision of a workforce where robots and humans collaborate fluidly. Optimus’s trajectory mirrors Tesla’s broader strategy: solve hard real-world automation first, then scale horizontally into new markets.

The Bottom Line

Tesla’s latest Optimus update transforms the project from a speculative moonshot into a tangible industrial tool. Dexterity, perception, and autonomy gains are aligning with factory economics, while shared learning loops compress iteration cycles. Whether or not Optimus becomes the first mass-produced humanoid, the company has redefined expectations for what rapid AI-driven robotics development looks like in practice.

About Timeless Quantity: Your daily lens on AI, space, and the digital future. Subscribe for deep dives, data-driven explainers, and hands-on guides.